Gone are the days when 3D printing was confined to prototyping. The technology is now emerging at the very heart of mass production. What once transformed ideas on a desktop into physical prototypes is now transforming factory lines, enabling tens of thousands of identical, high-quality products to be produced at industrial scale.

At the center of this transformation is GLUCK, a leading 3D printing service company redefining digital manufacturing from its smart factory in Paju, South Korea. GLUCK has implemented a fully integrated 3D printing-based foundry system, offering everything from product design to finished goods production. Far from simply following trends, GLUCK is pioneering a new model for digital manufacturing in Korea.

What Is a Digital Foundry? A New Standard in Manufacturing

You may recognize the term “foundry” from the semiconductor industry, where it refers to companies that manufacture chips based on fabless clients’ designs. The same concept is now being applied across the manufacturing sector, evolving into what’s known as a digital foundry.

A digital foundry is a made-to-order production system where physical molds and complex setups are no longer required. As long as there is a digital 3D design file, products can be manufactured directly. And the key technology enabling this transformation? 3D printing.

In traditional manufacturing, creating molds for production could cost tens or hundreds of thousands of dollars and take weeks or even months. Making design changes mid-process was difficult and costly, making small-batch or customized production nearly impossible.

But a digital foundry powered by 3D printing eliminates these constraints:

- No need for molds: Save significantly on time and upfront costs.

- Design agility: Instantly reflect design changes or custom requirements.

- Mass customization: Produce hundreds or thousands of units, each with unique specs.

- Democratized production: Anyone with an idea can now bring their product to market without the need for complex infrastructure.

GLUCK has emerged as Korea’s most practical and systematic executor of this digital foundry model. Its smart factory in Paju functions as more than just a print shop — it’s a production plant capable of delivering scalable, repeatable, high-quality results.

From Design to Delivery: GLUCK’s All-in-One Production System

Mass production isn’t just about making many copies of a product. It’s about ensuring that the first and the thousandth unit are identical in quality — and that reorders can be fulfilled under the same consistent conditions.

Since its founding in 2016, GLUCK has systemized and standardized its entire production process — from design and printing to post-processing and quality control — based on years of manufacturing experience. Here’s how GLUCK turns ideas into finished products:

1. Design & Process Engineering

Every project begins with a fundamental question: “Why does this product need to exist?” GLUCK’s engineers analyze the end-use and operational environment to define necessary functions and performance. They then select optimal materials and design the entire manufacturing process, from build strategy to post-processing.

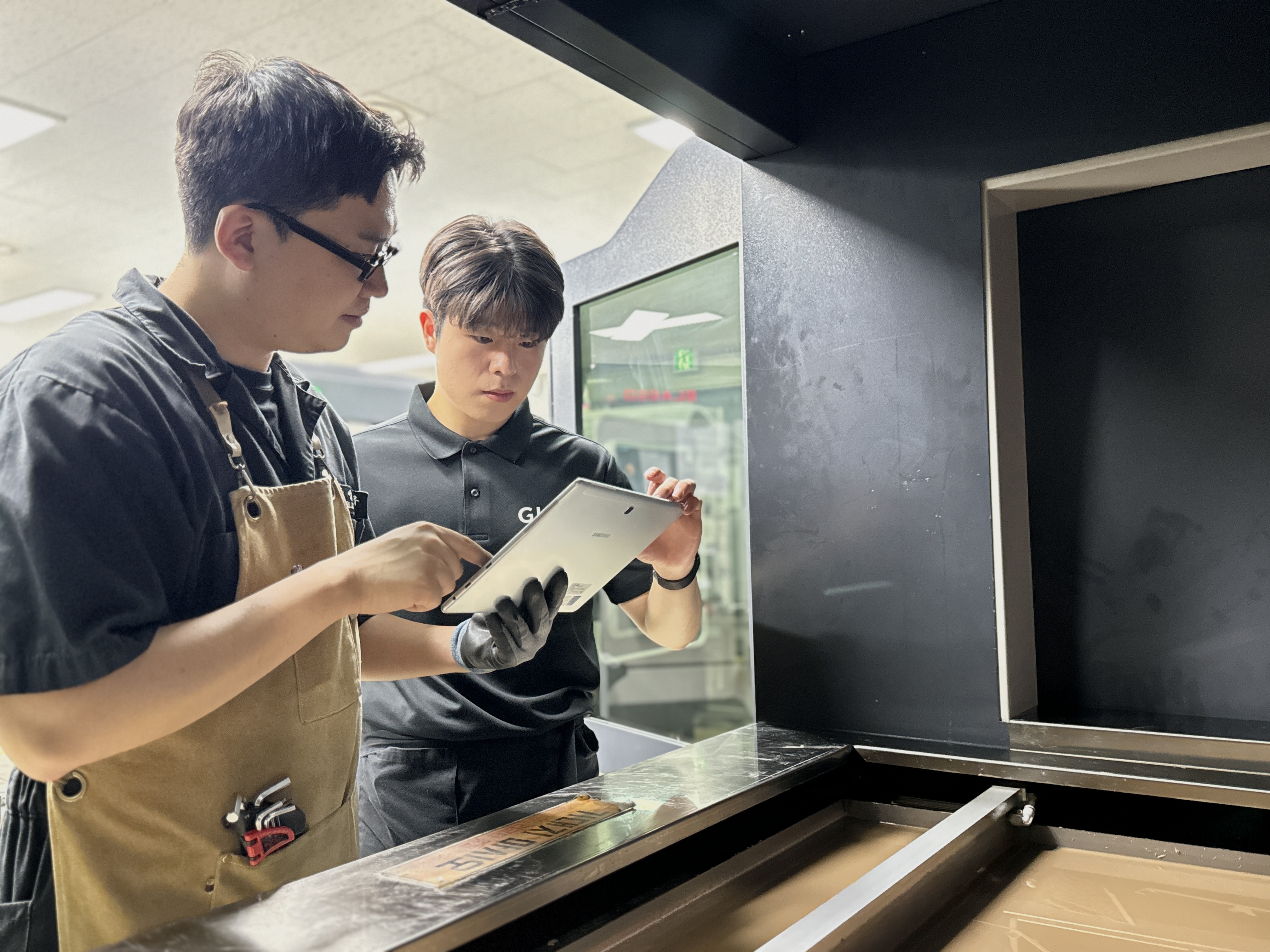

2. 3D Printing & Manufacturing

The production process is carried out at GLUCK’s smart factory, where dozens of industrial 3D printers operate 24/7. Each item is precisely printed based on its intended use — whether for electronics, healthcare devices, or industrial applications.

3. Post-Processing & Quality Control

A printed part is not a finished product. Post-processing — including surface finishing, painting, coating, and assembly — is essential for the product to meet industrial standards. GLUCK internalizes all these steps, meticulously documenting every parameter: material mix ratios, machine settings, processing time, inspection criteria, and more. This level of detail enables tight control over repeatability and product consistency.

As CEO Jae-Ok Hong states:

“We begin by understanding the reason a product exists and tailor the manufacturing process to meet that goal. Over time, we’ve built a foundation that allows us to adapt quickly to changing demands. Today, we’re capable of completing most work entirely within our factory.”

This streamlined system delivers one critical value to clients: trust. No matter when or how many times they order, GLUCK guarantees identical high-quality products every time.

→ Read the original article on Seoul Economic Daily

글룩 '플라스틱 3D 프린팅으로 맞춤형 대량생산 시대 열 것'

산업 > 중기·벤처 뉴스: “3D 프린팅 활용범위는 무궁무진합니다. 소비자 취향이 다양해지고 제품 수명 주기는 갈수록 짧아지는 흐름에 발맞춰 ‘맞춤형 ...

www.sedaily.com

Market Growth in Numbers: Why GLUCK’s Vision Matters

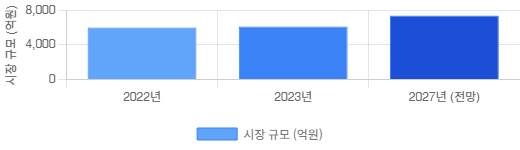

GLUCK’s bold direction aligns with explosive growth in the global and domestic 3D printing market. According to South Korea’s Ministry of Trade, Industry and Energy, the domestic 3D printing market — valued at approximately KRW 620 billion in 2023 — is projected to reach KRW 740 billion by 2027, growing at an average annual rate of 9–10%.

Applications in manufacturing (67%) and medical/healthcare (25%) are leading the way, while advancements in metal and composite materials are opening doors to high-value sectors like aerospace and defense.

The global outlook is even more dramatic. Research firms forecast the industrial 3D printing market to reach $30.2 billion by 2025. In the U.S., Europe, and China, digital manufacturing ecosystems — where design, production, and supply chains are interconnected through the cloud — are rapidly expanding. For digital foundries like GLUCK, this represents a world of opportunity.

GLUCK is now expanding its partnerships beyond Korea, positioning itself as a trusted manufacturing partner — not just a production vendor — helping clients scale globally with confidence.

Bring Your Idea to Mass Production — with GLUCK

The shift toward 3D printing-based mass production is no longer a distant future. It’s happening now.

The barriers of tooling, inventory, and inflexibility are falling away. Anyone with a compelling idea can now launch their product quickly and at scale.

GLUCK is Korea’s premier industrial 3D printing service provider, specialized in scalable, high-quality mass production.

#3DPrinting#AdditiveManufacturing#Industrial3DPrinting#MassProduction#DigitalManufacturing#DigitalFoundry#SmartFactory#AdvancedManufacturing#OnDemandManufacturing

'글룩 소식 (GLUCK News)' 카테고리의 다른 글

| [월간글룩. 2월] 맞춤형 3D프린팅 라이프아이템 추천 (1) | 2025.08.27 |

|---|---|

| [월간글룩. 2월] 2025년, 3D프린팅 제조 서비스 올해의 기업 선정 (0) | 2025.08.27 |

| 3D프린팅, 이제는 '대량생산'입니다: 글룩이 여는 디지털 파운드리의 시대 (0) | 2025.07.22 |

| Why must South Korea's manufacturing industry move beyond “outsourcing production to China”? (0) | 2025.07.02 |

| 대한민국 제조업은 왜 ‘중국 출력 대행’을 넘어서야 하는가? (1) | 2025.07.01 |